T: +86-20-36204500

No. 3, Lane 3, Junmin East Road, Hebian, Baiyun District, Guangzhou

Views: 0 Author: Site Editor Publish Time: 2025-08-21 Origin: Site

Business Size | Best Choice | Main Reason |

|---|---|---|

Large Enterprises | Automatic Filling Machine | High speed and efficiency |

Small & Medium (SMEs) | Semi-automatic Filling Machine | Flexibility and lower cost |

How much you make, your budget, workers, and plans for growth all help you decide. Think about what is most important for your business before you look at your choices.

Automatic filling machines are very fast and need fewer workers. They are best for big companies that make a lot of products. Semi-automatic filling machines cost less money and are more flexible. They are good for small or medium businesses or if your products change often. Think about how much you make, your money, workers, space, and future plans before you pick a machine. Automatic machines save time and cut down on waste, but they need more space and skilled workers to fix them. Semi-automatic machines are easier to use and fix. Use the checklist to match your product, how exact you need to be, and your budget with the right filling machine. Ask an expert for help if you need it.

At Huayang Machinery, we make many types of filling machines. We help the cosmetics, pharmaceutical, and food industries. Our team builds mixing machines and advanced filling equipment. You can use our machines for creams, lotions, syrups, and sauces. We have both automatic and semi-automatic filling machines for your needs.

Filling machines come in different types. You can pick one based on your product and how much you want to automate. Here is a quick guide to the main types and their automation levels:

Filling Machine Type | Description / Examples | Automation Level Categories |

|---|---|---|

Pouch Filling Machines | These fill pouches of many sizes and seal them to keep things fresh | Manual, Semi-automatic, Fully automatic |

Bottle Filling Machines | These fill bottles with powders, granules, or liquids; some can also cap bottles | Manual, Semi-automatic, Fully automatic |

Jar Filling Machines | These fill jars with care and often work with conveyor systems | Manual, Semi-automatic, Fully automatic |

Liquid Filling Machines | These handle many liquids, from water to thick creams | Manual, Semi-automatic, Fully automatic |

Powder Filling Machines | These fill powders and granules, including volumetric filling machines | Manual, Semi-automatic, Fully automatic |

Capsule Filling Machines | These are used for capsules in pharmaceutical production | Manual, Semi-automatic, Fully automatic |

If you have a big business or need to fill many containers fast, you should look at a fully automatic liquid filling machine. This machine uses motorized conveyors and sensors to move and fill containers with little help from workers. You can set it for different container sizes and filling amounts. The automatic liquid filling machine uses advanced PLC controls for accurate dosing and changes. You get high speed, steady output, and need fewer workers. This makes it great for high-volume jobs in cosmetics, food, and pharmaceuticals. Inline filling machines and rotary filling machines are both good for automatic lines.

Tip: Automatic liquid filling machines help you save time and make fewer mistakes. You can make more products as your business grows.

A semi-automatic filling machine is good for small and medium businesses. An operator puts containers in place and starts the filling, usually with a button or foot switch. The machine does the filling, but you control how fast it goes. This type costs less than a fully automatic liquid filling machine and is good for businesses with lower needs or smaller budgets. You can use semi-automatic filling machines for cleaning detergents, pharmaceutical products, and special foods. They are flexible and simple to use, so they are smart for custom or seasonal jobs.

Main Differences at a Glance:

Automatic liquid filling machines: Fast, need less labor, best for large jobs.

Semi-automatic filling machines: Cost less, need more manual steps, best for small to medium jobs.

You can always ask us at Huayang Machinery to help you pick the right filling machine for your business.

When you look at filling machines, you should see which one fits your needs best. Automatic fillers and semi-automatic fillers are strong in different ways. The table below puts their main features next to each other:

Feature | Automatic Filling Machines | Semi-Automatic Filling Machines |

|---|---|---|

Level of Automation | High; works with little help from people. | Medium; you do some steps in the filling process. |

Production Capacity | Fills big batches; best for fast and efficient work. | Good for small or medium batches; can fill many products. |

Precision | Very accurate (±0.2% to ±0.3%); keeps filling steady. | Good accuracy (±0.5%); you can watch and change as needed. |

Ease of Use | Needs skilled setup; runs by itself after you set it up. | Simple controls; most workers can learn to use it. |

Labor Requirements | Needs few workers; most steps happen automatically. | Needs more workers to load and unload containers. |

Equipment Cost | Costs more; you pay more at first for better speed and work. | Costs less; good for smaller budgets and gives good value. |

Maintenance | Needs skilled care; has more complex parts. | Easier to take care of; most workers can do basic care. |

Space Requirements | Takes up more room; best for big factories. | Small size; fits well in small or medium spaces. |

Integration | Connects with other machines for a full line. | Works alone or with simple setups. |

Flexibility | Best for one kind of product or container; not very flexible. | Can fill many kinds of products and containers; easy to change. |

Applicable Scenarios | Big factories, lots of products, steady demand. | Startups, small or medium businesses, changing or seasonal needs. |

Note: Automatic fillers give you the fastest work and best speed. Semi-automatic fillers are more flexible and cost less.

You want your filling machines to work quickly and fill each container with the right amount. The table below shows how automatic and semi-automatic filling machines perform:

Aspect | Automatic Filling Machines | Semi-Automatic Filling Machines |

|---|---|---|

Speed | Fastest speed; up to 50% faster than old systems. | Medium speed; faster than manual, slower than automatic. |

Accuracy | Very precise; best for expensive products. | Good accuracy; works for most products. |

Labor | Needs little labor; one person can watch many machines. | Needs more labor; workers load and unload containers. |

Cost | High starting cost; saves money later with better work. | Lower starting cost; good for small budgets. |

Scalability | Easy to add more machines or features as you grow. | Some add-ons possible; best for slow, steady growth. |

Consistency | Keeps filling the same every time. | Good consistency; workers can check each batch. |

Compliance | Meets GMP and ISO rules with real-time checks. | Can meet rules; needs more checks by workers. |

Automatic filling machines give you the best speed and quality. You get steady work and less waste.

Semi-automatic filling machines balance cost and how well they work. You get good accuracy and can change things for new needs.

Tip: If you want to make things faster and better, automatic fillers are best. If you need to save money and want more options, semi-automatic machines are a good choice for many businesses.

Picking the right filling machine depends on a few big things. You should think about how much you want to make, how much money you can spend, how many workers you have, how much space you have, and if you want to grow your business. Let’s talk about each thing to help you choose the best machine for you.

Production volume is very important. If you need to fill thousands of containers every day, an automatic filling machine works best. These machines fill lots of containers quickly and keep your work steady. You can fill things fast and finish big orders on time.

If your business is new or you make smaller batches, a semi-automatic filling machine may be better. You can fill different products without changing everything. This helps if you have special or seasonal products. You can also get a bigger machine later if you need to make more.

Tip: If you fill over 10,000 units a day, automatic filling machines help you reach your goals faster. If you fill 1,000 to 10,000 units a day, semi-automatic machines give you good speed and control.

Your budget is a big part of your choice. Automatic filling machines cost more at first, but they save money later. They use fewer workers and waste less material. For example, a business with an automatic system needs fewer workers and makes more products. These machines are easy to take care of and do not break down often.

Semi-automatic filling machines cost less to buy. They are a smart pick if you want to save money but still work better. You can get your money back in 12 to 18 months if you fill 1,000 to 10,000 units a day. These machines use less energy and are cheaper to fix.

Feature | Automatic Filling Machine | Semi-Automatic Filling Machine |

|---|---|---|

Initial Purchase Cost | Higher upfront cost | Lower upfront cost |

Maintenance | More complex and costly | Simpler and less costly |

Labor Requirement | Minimal human involvement | Requires more labor |

Scalability | High output, easy to expand | Best for small to medium volumes |

Note: Automatic machines save money if you use them a lot. Semi-automatic machines are great for new brands with small budgets.

Labor is another thing to think about. Automatic filling machines only need a few skilled workers to set up and check the system. Most jobs happen by themselves, so your workers can do other important things. This setup helps stop worker tiredness and injuries. It also keeps your work steady even if you have fewer workers.

Semi-automatic filling machines also use less manual work than fully manual systems. You still need people to load and unload containers, but some workers can do other jobs like customer service or checking quality. Many businesses work faster and need fewer workers after switching to semi-automatic or automatic machines.

Semi-automatic machines let workers do other jobs.

Lower labor costs and fewer injuries make work safer.

Automation keeps work steady and helps if you have fewer workers.

Many people say they work faster and need fewer hours.

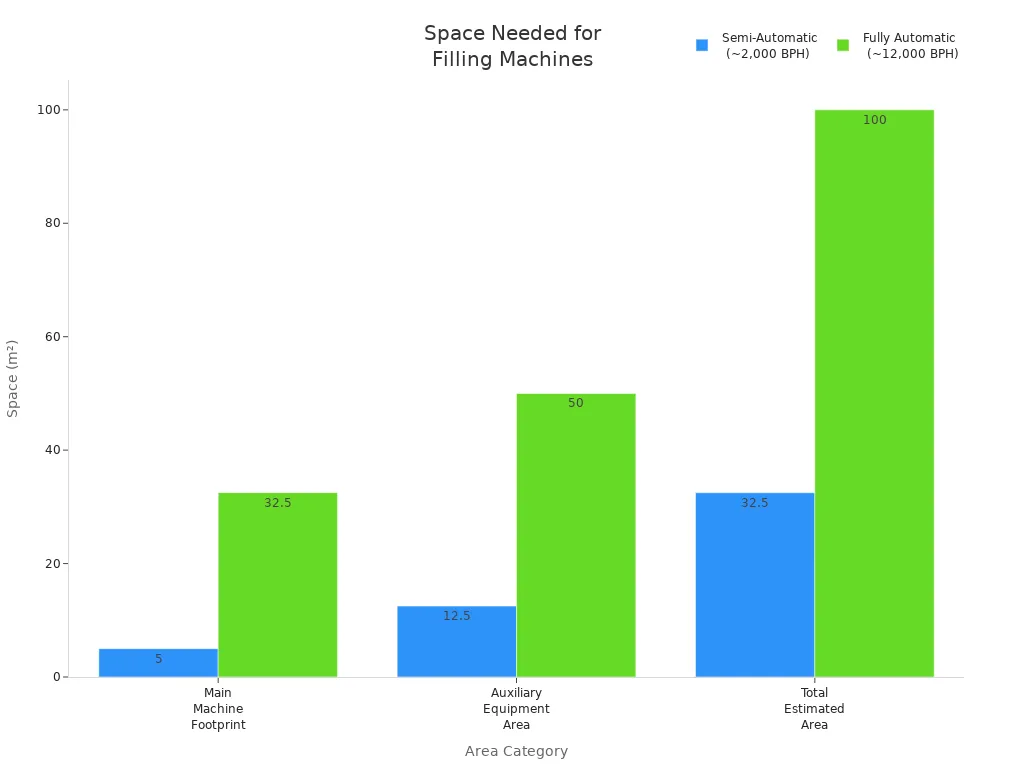

Space in your building can change what you pick. Automatic filling machines need more room because they have conveyors, sensors, and extra equipment for cleaning and fixing. You should plan for about 80-120 square meters for a full automatic system. This includes space for extra equipment and room for workers to move.

Semi-automatic filling machines are smaller. You can put them in small spaces, usually needing only 25-40 square meters. These machines are often straight, so you can put them by a wall or in a corner. This makes them good for small or medium factories.

Note: Always check your space before you pick a filling machine. Make sure you have enough room for the machine and for workers to move safely.

Scalability means how easy it is to make more products as your business grows. Automatic filling machines are made for big jobs. You can add more machines or new features like AI diagnostics and IoT integration to work better and meet high standards. This makes them best for big factories with lots of orders.

Semi-automatic filling machines have a modular design. You can add more fill stations or conveyor systems as you grow. Many businesses start with a semi-automatic machine and get bigger ones later. This lets you spend money step by step, which helps if you make different products or small batches.

Semi-automatic machines let you grow by adding new parts.

You can use main parts again when you upgrade to more automation.

These machines are a good first step for businesses that want to grow slowly.

At Huayang Machinery, we know every business is different. We make many kinds of filling machines, mixing machines, and emulsifying mixers for cosmetics, pharmaceuticals, and food. Our team can make your filling equipment fit your product, your goals, and your space. If you need a small semi-automatic filling machine for a new business or a full automatic filling line for high production, we can help. Our machines work with different automation levels and can be changed for many product types and sizes, so you always get good quality and efficiency.

You can make more products with an automatic liquid filling machine. Many companies like these machines because they help in many ways.

You fill more containers quickly. This helps you keep up with lots of orders.

Automatic fillers use smart technology. They make sure each container gets the same amount. This means less waste and fewer mistakes.

You need fewer workers. You also waste less product. This helps you save money.

These machines help you follow hygiene rules. This is important for food and medicine companies.

You can change the machine for different products and sizes.

New features like IoT and robots help you watch and fix your equipment right away.

A fully automatic liquid filling machine can make your work up to 50% faster than manual machines. You also get quick checks for quality and steady work.

Automatic filling machines can have some problems. Here are some common ones.

Sometimes the fill levels are not the same. Air pockets or old nozzles can cause this.

Nozzles may drip or leak. This happens if seals are worn or not lined up.

The machine might not start or could stop. Electrical problems or bad sensors can cause this.

Bottles can be in the wrong place or get stuck. This happens if the conveyor is not lined up.

Flow rates can change. Clogs or thick products can cause this.

Foam can form if you fill too fast or the nozzle is not set right.

Air compressor or vacuum problems can happen. Bad care can cause these issues.

Checking your machine often and taking care of it helps stop most problems.

A semi-automatic filling machine helps small and medium businesses in many ways.

You fill more products each day than with manual machines.

You get good accuracy and less waste. Your products are better.

You can use the machine for many products and container sizes.

It costs less, so you can grow without spending too much.

The machine is small and easy to clean. This saves space and time.

Simple controls help your team learn fast and work safely.

A semi-automatic filling machine gives you a good mix of speed and cost.

Semi-automatic filling machines have some limits you should know.

They are slower than fully automatic liquid filling machines. This can be a problem as you get bigger.

You need at least one worker to run the machine. Labor costs stay higher.

People can make mistakes. This can change how much goes into each container.

To grow, you need more machines and more workers. This is not as good as automation.

You need to check and adjust the machine often. This can stop work for a while.

Limitation | Explanation |

|---|---|

Lower Production Speed | Slower than automatic systems, so you may get stuck with big orders. |

Ongoing Labor Requirements | Needs a worker all the time, which costs more. |

Potential for Human Error | Mistakes can change product quality and how much goes in each container. |

Limited Scalability | Adding more machines and workers is not as easy as using automation. |

If you want to grow quickly, you may need to switch to an automatic liquid filling machine to work faster and better.

Automatic filling machines work in many industries. In cosmetics, swirl filling machines make creams with nice layers. These machines fill containers fast and make products look cool. Food factories use volumetric and liquid fillers for sauces and drinks. You get quick, clean, and exact filling. This keeps products safe and fresh. Pharmaceutical companies use automatic filling machines for liquid medicines. You follow strict rules and every dose is the same. Chemical plants use these machines for big packs of industrial liquids. Each container gets the right amount.

Industry | Application Example | Benefit |

|---|---|---|

Cosmetics | Swirl filling for dual-toned creams | Attractive products, less waste |

Food & Beverage | Volumetric fillers for sauces and drinks | Fast, hygienic packaging |

Pharmaceuticals | Liquid medication filling | Accurate dosing, compliance |

Chemicals | Bulk liquid packaging | Precise dispensing |

Automatic filling machines save time and cut waste. You meet high standards and can make more products as your business grows.

Huayang Machinery gives you advanced filling machines for many industries. We make solutions for your products and how you work. Our team helps you anywhere in the world with good service and support.

Semi-automatic filling machines give you more control and choices. Cosmetics makers use lotion and lip gloss filling machines for new products and different containers. You can change products easily. Pharmaceutical companies use semi-automatic vial fillers to keep doses right and stop contamination. Food businesses fill honey, sauces, and dairy with these machines. Production stays clean and works well. Chemical companies use special filling equipment for safe handling of strong materials.

Semi-automatic filling machines help small businesses or those growing slowly.

You can change settings and start filling yourself. It is easy to handle different products.

These machines help you grow and keep costs low.

Huayang Machinery has semi-automatic filling machines for your space and budget. We design equipment for creams, liquids, powders, and more. Our team works with you to make solutions that fit your goals. You get help from our R&D centers and after-sales service. Your equipment will work well.

Tip: Pick semi-automatic filling machines if you want more choices and easy upgrades as your business gets bigger.

Picking the right filling machine can seem hard. You want your choice to fit your products and how much you make. It should also match your plans for the future. Use this checklist to help you decide and avoid mistakes.

Check if your product is thin, thick, or chunky.

Some machines work better with liquids. Others fill creams or powders.

If your product foams or has bits, pick a machine that can handle these.

Tip: Match the filling mechanism to your product’s viscosity and texture. This stops spills and keeps things running well.

Count how many containers you fill each day or shift.

If you fill a lot, you may need an automatic filling machine.

If you fill less or your needs change, semi-automatic machines might be better.

Production Volume | Best Machine Type |

|---|---|

High (10,000+ units) | Automatic |

Medium (1,000-10,000) | Semi-Automatic or Auto |

Low (<1,000 units) | Semi-Automatic |

Look at the size, shape, and opening of your containers.

Make sure the machine can fill your bottles, jars, or pouches without leaks.

Quick change features help if you use many container types.

Decide how exact you want each fill to be.

For medicines or expensive products, pick a machine with high precision.

For other products, standard accuracy may be fine.

Think about the price and long-term costs.

Automatic machines cost more at first but save on labor and time.

Semi-automatic machines cost less and are easier to care for.

Note: Balance your budget with your production goals. Saving now can cost more later if the machine cannot keep up.

Check how many workers you have and what they know.

Automatic machines need fewer workers but need technical skills.

Semi-automatic machines give you more control and flexibility.

Measure your floor space.

Automatic systems need more room for conveyors and extra equipment.

Semi-automatic machines fit in smaller spaces.

Think about how your business might grow. Pick a machine that can grow with you.

Make sure the machine fits with your current production line.

Check if the machine meets rules like GMP or CE.

Ask about support, spare parts, and training.

Ask for a demo or sample run with your product.

This helps you see if the machine works well with your product and containers.

Do not ignore your product’s viscosity.

Always check nozzle and container compatibility.

Never pick the cheapest option without checking quality.

Make sure the machine speed matches your needs.

Plan for easy care and good support.

Talk to trusted manufacturers like Huayang Machinery.

Ask for advice from experts.

Use support for setup, training, and fixing problems.

Request demos to see how the machine works.

Remember: Involve your team and get expert advice. This helps you make the best choice for your business.

Quick Checklist Table

Step | What to Check | Why It Matters |

|---|---|---|

Product Characteristics | Viscosity, bits, foaming | Helps you pick the right machine |

Production Volume | How much you fill each day | Matches machine to your needs |

Container Type | Size, shape, opening | Stops leaks and spills |

Accuracy | Fill precision | Reduces waste, meets standards |

Budget | Price and long-term costs | Balances cost and efficiency |

Labor & Automation | Staff skills, automation level | Makes work easier |

Space & Scalability | Floor space, future growth | Supports expansion |

Compatibility & Compliance | Integration, certifications | Keeps quality, avoids fines |

Testing | Demo or sample run | Checks if machine is right |

Support | After-sales, training, spare parts | Cuts downtime |

✅ Use this checklist before you choose. The right filling machine helps your business grow, saves money, and keeps your work running smoothly.

Picking the right filling machine helps your business do well. Automatic filling machines are good for making lots of products fast. They help your business grow and stay strong. Semi-automatic filling machines are better for small batches and saving money. They also work well if you need to change things often.

The kind of product, how much you make, and how the machine works all change how well your business does.

Using automation means you need fewer workers. You can make more products and keep the quality good.

Taking care of your machine and getting help when needed makes it last longer.

Think about what you want for your business, check the list, and let Huayang Machinery help you find the best filling machine for your future.

Automatic filling machines work by themselves after setup. You do not need to help them fill containers. Semi-automatic filling machines need you to put containers in place. You also start the filling process. Both types are faster than filling by hand.

A semi-automatic filling machine is a smart choice. It costs less money and fits in small rooms. You can use it for many products, like creams or liquids. This machine lets your business grow slowly and safely.

Yes! Huayang Machinery can make a filling machine just for you. The team can change the machine for different sizes and shapes. They can also adjust it for powders, liquids, or creams.

Count how many containers you fill every day. If you fill more than 10,000 units, choose an automatic filling machine. If you fill less, a semi-automatic filling machine is better. You can upgrade your machine when your business gets bigger.

Yes! Huayang Machinery makes machines that follow GMP and ISO rules. You get safe and strong equipment for cosmetics, medicine, and food.

Need help picking a machine? Contact Huayang Machinery for expert help and a free talk.