T: +86-20-36204500

No. 3, Lane 3, Junmin East Road, Hebian, Baiyun District, Guangzhou

Views: 0 Author: Site Editor Publish Time: 2025-09-09 Origin: Site

You use several machines to manufacture toothpaste, including mixing machines, homogenizers, deaerators, filling equipment, sealing and packaging units, and quality control tools. Modern solutions, such as the Toothpaste Making Machine from HUAYANG, deliver advanced capabilities like high viscosity mixing, vacuum emulsifying, and automation.

With these machines, you benefit from faster packaging, lower labor costs, reduced waste, and the flexibility to handle multiple tube sizes and materials.

When you step into a toothpaste manufacturing facility, you encounter a series of specialized machines designed to transform raw ingredients into a smooth, market-ready paste. Each machine plays a critical role in ensuring product consistency, safety, and efficiency. You rely on these machines to blend, homogenize, and package toothpaste with precision.

Tip: Using advanced equipment like the HUAYANG Toothpaste Making Machine can help you achieve consistent quality and streamline your production process.

You start with precision mixing systems. These machines blend water, glycerin, silica, and surfactants, controlling viscosity and texture. You adjust mixing speeds to suit different formulations, such as whitening or therapeutic pastes. High viscosity homogenizers come next. You use them to process thick ingredients, ensuring a uniform emulsion and smooth texture.

Vacuum emulsifying mixers allow you to combine water, oil, and powders under vacuum. This step prevents air bubbles and contamination, giving your toothpaste a flawless finish. Dispersing and milling equipment break down particles and agglomerates, refining the paste to the desired consistency.

You also depend on ancillary equipment to support the main production line. Transfer pumps move the viscous paste to filling machines. Inline filters remove impurities, and automation systems let you monitor and control every stage of production.

Here is a quick overview of the essential machines:

| Machine Type | Main Function |

|---|---|

| Precision Mixing Systems | Blend ingredients, control viscosity |

| High Viscosity Homogenizers | Emulsify thick components |

| Vacuum Emulsifying Mixers | Combine phases, remove air |

| Dispersing & Milling Tools | Refine texture, break down particles |

| Ancillary Equipment | Transfer, filter, automate processes |

With these machines, you gain the ability to produce toothpaste efficiently, maintain high standards, and adapt to changing market demands.

You rely on precision mixing systems to blend water, glycerin, silica, and surfactants. These machines ensure every ingredient hydrates quickly and evenly.

The continuous mixing pattern guarantees rapid and complete hydration of thickening agents, essential for achieving the desired toothpaste consistency.

You achieve a homogeneous mixture with these systems, which is vital for consistent texture and quality.

Proper mixing at every step is necessary to achieve lot-to-lot consistency and ensure that each ingredient fully imparts its intended functionality.

When you work with thick formulations, high viscosity homogenizers become essential.

These machines handle dense pastes that standard homogenizers cannot process efficiently.

They use high pressure to generate strong impact forces, which improves dispersion and creates a stable emulsion.

You benefit from enhanced uniformity and stability in your toothpaste batches.

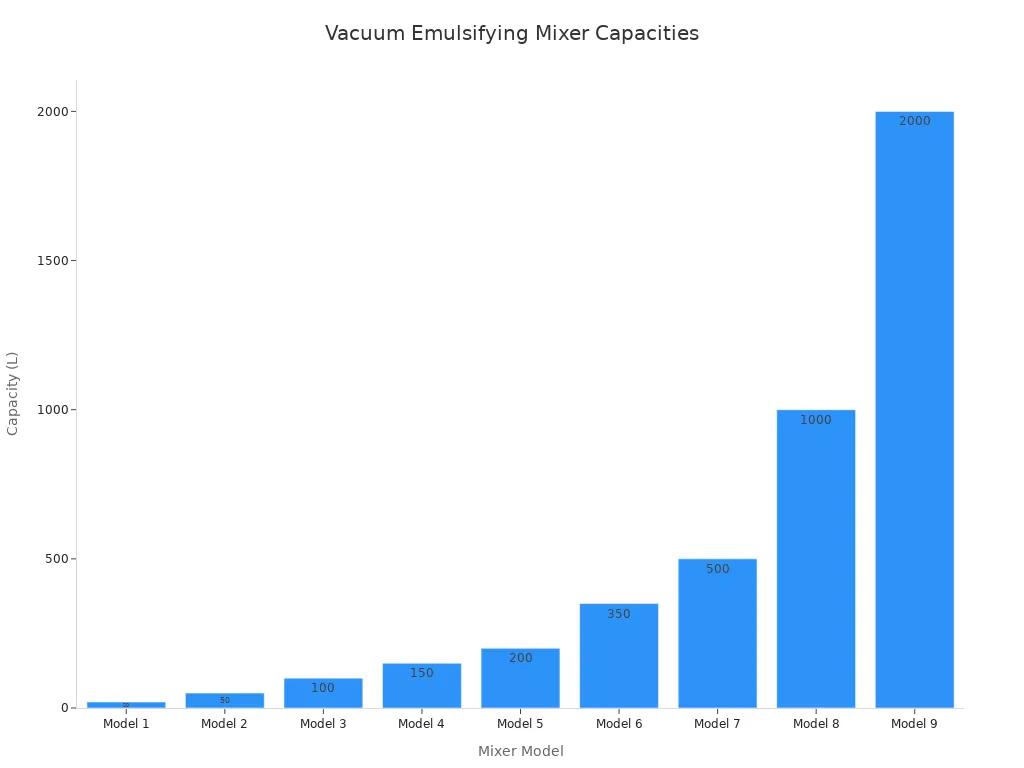

Vacuum emulsifying mixers combine water, oils, and powders under vacuum conditions. This process removes air bubbles and prevents contamination. You can choose from a wide range of capacities to match your production needs.

| Model | Effective Capacity (L) |

|---|---|

| Model 1 | 20 |

| Model 2 | 50 |

| Model 3 | 100 |

| Model 4 | 150 |

| Model 5 | 200 |

| Model 6 | 350 |

| Model 7 | 500 |

| Model 8 | 1000 |

| Model 9 | 2000 |

You use dispersing and milling equipment to refine the texture of your toothpaste.

High-shear mixing ensures uniform particle size.

Advanced milling breaks down larger particles, achieving sizes from 2–10 μm or even smaller.

You can adjust parameters like pressure and temperature for precise control over the final product.

Ancillary equipment supports your main production line.

| Machine Category | Primary Function |

|---|---|

| Filling Line Machine | Fills toothpaste into containers. |

| Packaging Machine | Packages finished toothpaste products. |

| Water Treatment Equipment | Prepares and treats water for production. |

| Liquid Material Storage Tanks | Stores raw liquid materials. |

| Rotor Pump | Transports viscous materials. |

| Centrifugal Pump | Moves water and other fluids. |

You integrate these machines with your Toothpaste Making Machine to streamline production and maintain high standards.

You follow a precise sequence when producing toothpaste to guarantee quality and consistency. Each step uses specialized equipment to transform raw materials into a finished product.

Prepare the liquid base using water, sorbitol, glycerin, and other liquid ingredients.

Pre-mix rheology modifiers with a non-aqueous liquid or dry blend with powdered ingredients.

Add and disperse the active ingredient, sweetener, and preservative.

Incorporate the abrasive or filler, either as a slurry or pre-mixed with water.

Add flavoring and coloring to achieve the desired taste and appearance.

Introduce the detergent last under slow speed agitation to minimize foaming.

Tip: You can optimize each step by using a Toothpaste Making Machine with automated controls, which helps maintain consistency and reduces manual errors.

You rely on different machines at each stage to ensure the toothpaste meets industry standards. Here is how each machine contributes to the process:

| Machine/Tool | Contribution to Quality Control |

|---|---|

| Sensors | Collect real-time data on temperature, pressure, and weight, influencing toothpaste quality and consistency. |

| Azure Functions | Run predictive models to anticipate the next stage of production, ensuring adherence to quality standards. |

| Power BI | Provide operators with visual dashboards to monitor the process and identify anomalies. |

You measure the effectiveness of quality control equipment using several methods:

Time Domain Nuclear Magnetic Resonance (TD-NMR) determines fluorine content quickly, ensuring health benefits and safety.

Viscosity testing with a rotational viscometer measures consistency, which affects handling and dispensing.

Texture analysis with a Texture Analyzer evaluates the force required to compress or expel toothpaste, providing insights into usability.

You use rotational viscometers to check thickness and handling, ensuring the product meets consistency standards. Texture Analyzers assess the force needed to manipulate toothpaste, giving you data on ease of use.

Note: Quality control equipment helps you maintain high standards and deliver a product that meets consumer expectations.

Selecting the right Toothpaste Making Machine for your facility requires careful evaluation of several criteria. You must assess machine performance, product compatibility, maintenance needs, and long-term financial impact. The following table outlines the main factors you should review:

| Criteria | Description |

|---|---|

| Machine performance | Evaluate accuracy, efficiency, intelligence, manufacturing speed, and product capacity. |

| Product formulation | Ensure compatibility with the specific ingredients and types of toothpaste being produced. |

| Maintenance | Consider the ease of maintenance and support from the manufacturer for long-term efficiency. |

| Return on investment (ROI) | Assess budget and costs to determine the financial viability of the machine over time. |

You should prioritize machines that offer precise mixing, reliable automation, and compatibility with your chosen formulations. Maintenance support from the manufacturer helps you minimize downtime and keep your production line running smoothly. When you invest in a machine with advanced features, you gain the ability to produce consistent, high-quality toothpaste and adapt to changing market demands.

Automation plays a key role in modern toothpaste manufacturing. Automated systems streamline production, reduce batch times, and ensure every tube meets strict quality standards. You also lower labor costs by automating repetitive tasks, allowing you to allocate resources more efficiently.

When you plan your investment, you must balance initial costs with long-term savings. Consider the following points:

Semi-automatic machines usually cost less upfront than fully automated systems.

Energy-efficient designs may increase the purchase price but help you reduce operational expenses over time.

Features like automatic cleaning and smart monitoring improve efficiency, though they require a higher initial investment.

Operational costs for your facility will rise over time due to inflation and market changes. Maintenance expenses depend on your operational context and economic factors. You should choose a machine that fits your budget while offering the features you need for reliable, efficient production.

Tip: Investing in a high-quality Toothpaste Making Machine with automation and energy-saving technology can help you achieve better results and lower costs in the long run.

You see rapid changes in toothpaste manufacturing as companies adopt new technologies to boost efficiency and product quality. Automation now plays a central role. Automated and semi-automated machines help you achieve higher throughput and adapt to different toothpaste viscosities. These systems also improve hygiene, which has become a top priority. In 2023, demand for automated filling machines grew by 7.8% as manufacturers upgraded their lines for safer, cleaner production.

You also benefit from smart manufacturing solutions. IoT-enabled machines let you monitor production in real time and predict maintenance needs, reducing downtime. Data analytics tools give you better control over the process, allowing you to fine-tune each batch. AI-powered customization tools now let you create personalized toothpaste formulas, which helps you meet changing consumer preferences.

Here is a summary of recent advancements:

| Advancement Type | Description |

|---|---|

| Automation | Boosts efficiency and capacity with automated processes |

| Data Analytics | Improves oversight and process optimization |

| Precision Manufacturing | Delivers consistent, high-quality toothpaste |

| IoT Integration | Enables real-time monitoring and predictive maintenance |

| AI Customization Tools | Supports personalized product development |

Note: The growth in automation reflects a shift toward safer, more efficient, and more flexible toothpaste production.

You can expect even more innovation in the future. Industry 4.0 technologies will transform the design and function of the Toothpaste Making Machine. IoT, artificial intelligence, and predictive analytics will make your manufacturing smarter and more responsive. Automated quality control and predictive maintenance will help you catch issues early and keep your line running smoothly.

Sustainability will shape the next generation of equipment. Manufacturers are moving toward biodegradable tubes, minimalist packaging, and refill programs to reduce waste. Energy consumption analytics and AI-driven quality control will help you lower your environmental impact. You will also see more use of recycled materials and local sourcing to cut emissions.

Sustainability and digital transformation will define the future of toothpaste production, helping you deliver quality products while protecting the environment.

You depend on several essential machines for consistent, high-quality toothpaste production:

High viscosity mixing machines

Homogeneous emulsifying mixers

Hose filling and sealing machines

Industrial blending tanks

Modern equipment, such as the Toothpaste Making Machine, offers advanced features that boost efficiency and product quality. These include precise ingredient blending, vacuum homogenization, and automated control panels for seamless operation.

| Feature | Benefit |

|---|---|

| Automation | Faster, more reliable output |

| GMP compliance | Enhanced safety and hygiene |

Choosing the right equipment ensures you deliver safe, effective toothpaste every time.

You use a Toothpaste Making Machine to blend, homogenize, and emulsify ingredients. This equipment ensures your toothpaste has a consistent texture, stable formulation, and meets safety standards.

You clean machines with automated CIP (Clean-In-Place) systems or manual washing. Regular maintenance checks help you prevent breakdowns and keep your production line running smoothly.

You can manufacture various toothpaste types, including whitening, fluoride, and herbal formulas. Advanced machines let you adjust mixing speed, viscosity, and temperature for each product.

You should choose machines with GMP compliance, stainless steel construction, and automated controls. These features help you maintain hygiene and protect your operators.

Automation lets you monitor production, reduce errors, and increase output. You benefit from lower labor costs and consistent product quality.